All the strength and durability of aluminium with all the appeal of natural wood.

Ideal for both interior and exterior use, we use the world’s fastest sublimation machine to reproduce photographic images of natural woodgrains, marbles, concretes and patina metals onto powder coated aluminium panels & extrusions.

We are pleased to announce our new MW 25/10 Warranty which provides for a 25 year warranty on the underlying powder coating and a 10 year warranty on the pattern. More details can be found in the warranty section.

- Doors

- Cladding

- Screens

- Fencing

- Gates

- Windows

- Soffits

- Awnings

- Pergolas

- Railings

- Ceilings

- Louvres

- Facades

- Garage Doors

- Partitioning ...

MetWood sublimated finishes exhibit the natural variations of colour, grain and blemishes that are seen in real wood.

Some finishes also exhibit some shifting of colour over time, similar to that of the actual product.

Durable - 25 year warranty on the underlying powder coating, 10 year warranty on the pattern

Virtually maintenance free

Fire rating benefits - Group Number 1-S internal fire rating and a Type A external rating

Lightweight

Non-warping

Impact & scratch resistant

Insect resistant

and it’s eco friendly!

Extensive range of finishes

We have an extensive range of finishes in stock, including native NZ timbers. And if you can’t find exactly what you’re looking for within our range just let us know, we have more finishes available than those shown on the website, so feel free to contact us if you have specific requirements.

Search our finishes by timber grain or by overall colour

Whether you're looking for a particular timber grain (e.g. cedar), or just have a general idea of the shade/colour of finish you want, you can find all of the MetWood finishes using the dropdown menu on the MetWood tab above, or by requesting a swatch.

Technical Information

The MetWood Process (Sublimation)

Our sublimation transfer films are sourced exclusively from our suppliers in Italy, where high definition photographic images of real timbers are printed onto the films using specially formulated sublimation dyes.

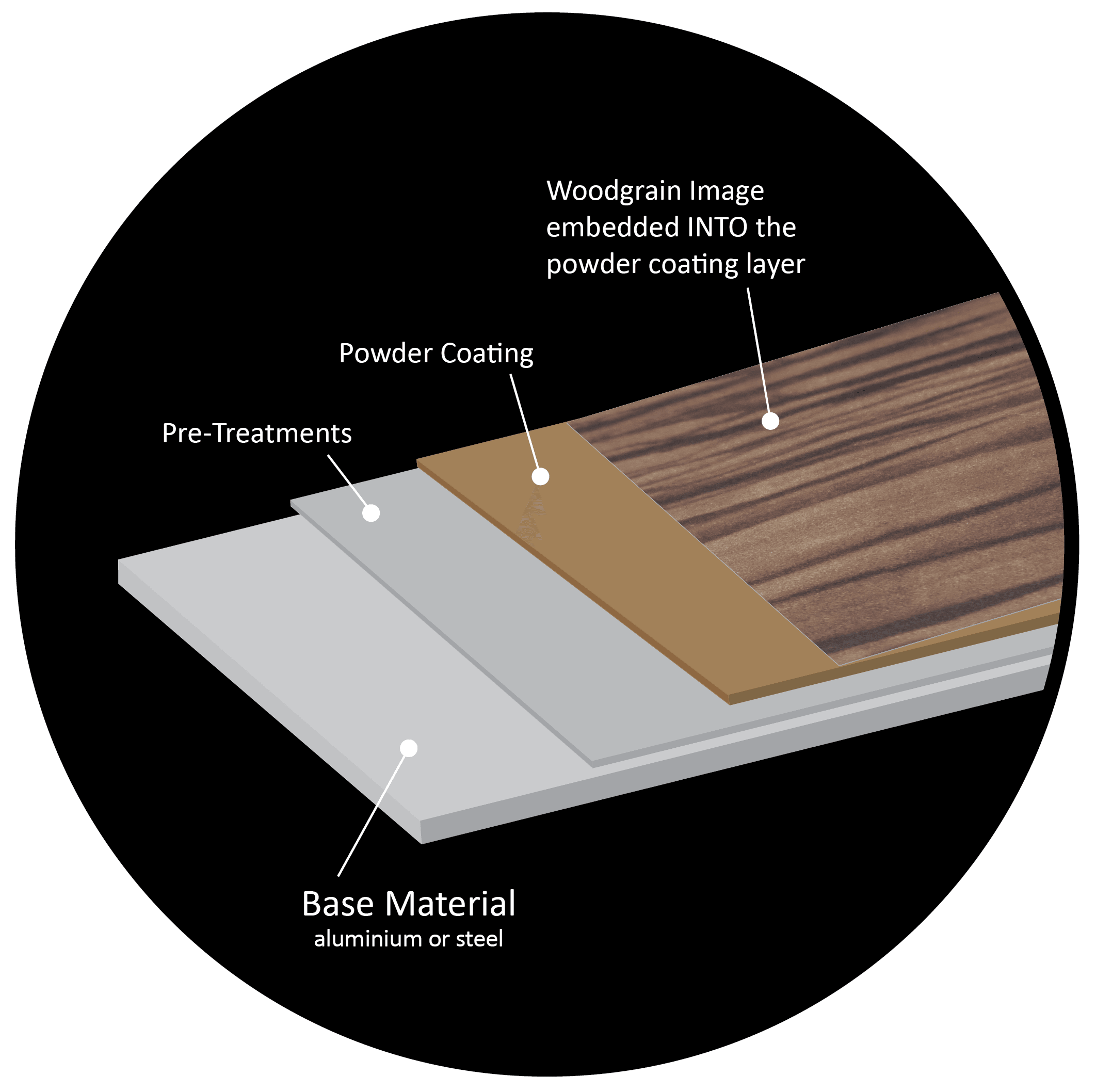

Your panel or extrusion is first powder coated using one of our specially formulated sublimation transfer powders.

The transfer film is wrapped around your powder coated profile, which then enters our state-of-the-art sublimation machine.

Vacuum suction is used to bring the film in contact with the powder coated finish under high pressure, while being heated to a temperature of up to 200 degrees.

The combination of pressure and temperature result in the printed image being lifted from the film and transferred INTO the molecules of the powder coat layer, where it becomes permanently embedded throughout its thickness, resulting in a long-lasting and extremely durable finish.

The transfer film is then removed.

Production Capabilities

ALUMINIUM

Extrusions up to:

7.2m long

300mm wide

6mm thick

Flat panels up to:

7m long

1220mm wide

3mm thick

For large, complex or heavy wall sections and folded panels please contact the Powder Coating Group

Environmentally friendly processes

Powder Coating is environmentally friendly

Powder Coatings offer not only a cost effective but environmentally sustainable option to alternatives such as Wet Spraying.

- No Volatile Organic Compounds (VOC's) produced

- Low emissions

- Minimal product waste

The sublimation process is environmentally friendly

- The sublimation ink makes up less than 1% of the weight of the completed profile

- Inks used are not engineered to be biodegradable, however, they are made of organic components, free of heavy and dangerous metals and other dangerous/hazardous/toxic substances

- No hazardous components are released under normal operations